Metals & Minerals

We market a wide range of metals and minerals

Stainless Steel

A Durable and Versatile Metal

Stainless steel is a metal alloy that is widely used in a variety of industries due to its excellent properties. It is corrosion-resistant, durable, and versatile, making it ideal for many applications.

It is made from iron, chromium, and other elements such as nickel, molybdenum, and titanium. The addition of these elements gives stainless steel its unique properties, such as corrosion resistance and strength.

One of the most versatile materials

Steel is one of the most versatile and widely used materials in various industries, ranging from construction to automotive. It offers a unique combination of strength, durability, and formability that make it an ideal material for different applications. However, the use of steel in its raw form, such as sheets or bars, can be limited due to its size, weight, and handling requirements. This is where steel coils come in.

Get In Touch

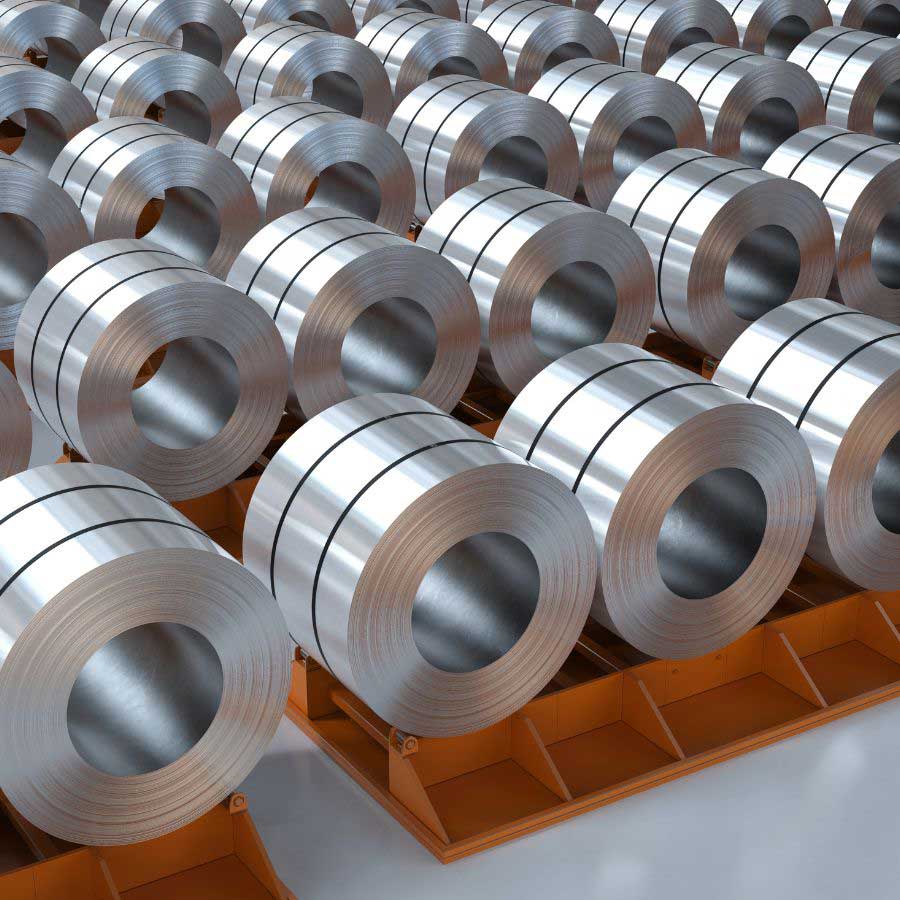

Steel Coils

If you are in the manufacturing industry or construction business, you may have heard about steel coils. But what are they, and how can they benefit your business?

Steel coils are flat, thin sheets of steel that are wound into a coil shape. They are made by processing raw steel through a series of rolling, annealing, and galvanizing processes to achieve specific properties and dimensions. Steel coils offer several advantages over traditional steel sheets, such as ease of handling, transportation, and storage, as well as improved consistency and quality.

Rolling Process

Steel coils are long, continuous strips of flat steel that have been wound into a coil shape. They are typically produced through a rolling process, which involves passing raw steel through a series of rollers to achieve the desired thickness, width, and surface finish. The resulting steel coils are then processed further, such as by annealing, galvanizing, or painting, to improve their properties and performance.

Types of Steel Coils

There are several types of steel coils available in the market, each with its unique properties and applications. Some of the most common types of steel coils include:

Hot-Rolled Steel Coils

Hot-rolled steel coils are produced by rolling raw steel through a series of heated rollers, which help to shape and form the steel into its final shape. The hot-rolling process produces steel coils with a rough surface finish and a slightly rounded edge, which makes them ideal for applications that do not require a high level of precision or surface finish.

Cold-Rolled Steel Coils

Cold-rolled steel coils are produced by rolling raw steel through a series of rollers at room temperature, which helps to improve the surface finish and dimensional accuracy of the steel. The cold-rolling process produces steel coils with a smoother surface finish and tighter dimensional tolerances, making them ideal for applications that require a high level of precision and surface finish.

Galvanized Steel Coils

Galvanized steel coils are produced by coating steel coils with a layer of zinc, which helps to protect the steel from corrosion and improve its durability. The galvanizing process involves dipping the steel coils into a bath of molten zinc or electroplating the steel with zinc to create a protective barrier on the surface.

Stainless Steel Coils

Stainless steel coils are made from a high-grade steel alloy that contains chromium and other elements that give it excellent corrosion resistance and durability. The stainless steel coils are produced by rolling the steel through a series of rollers and then annealing the steel to improve its strength and ductility.

Iron

Iron is a hard, strong, and silvery-grey metal that is commonly used in construction, manufacturing, and engineering.

Iron is a metallic element with a silvery-grey color that is easily magnetized and rusts readily in moist air. Iron is the fourth most abundant element in the Earth’s crust, and is found in many minerals such as hematite, magnetite, and taconite. It is also the most widely used of all metals, with an enormous range of applications that includes construction, transportation, and manufacturing.

One of the most important uses of iron is in the production of steel, an alloy made by mixing iron with carbon and other elements such as nickel, chromium, and manganese. Steel is one of the most versatile and widely used materials in the world, used in everything from buildings and bridges to cars and appliances.

Nickel

One of the most common uses of nickel is in the production of stainless steel, where it is alloyed with chromium and other metals to improve its strength and resistance to corrosion. Nickel is also used in the production of other alloys, including Inconel and Monel, which are used in high-temperature and high-pressure applications such as jet engines and chemical processing equipment.

In addition to its use in alloys, nickel is also used in batteries, particularly in rechargeable nickel-cadmium batteries and nickel-metal hydride batteries. These batteries are used in a wide range of applications, from portable electronics to electric vehicles.

India’s significant reserves of nickel, along with its growing production capacity, make it an important player in the global nickel industry, with the potential to play a significant role in meeting the world’s growing demand for this vital metal. India’s nickel production has been increasing steadily over the years, with the country producing around 39,000 metric tons of nickel in 2020. The majority of the nickel produced in India is used for the production of stainless steel, which is used in various industries such as construction, automotive, and aerospace.

Copper

Copper is a reddish-brown metal that is well-known for its excellent electrical conductivity and malleability. It is commonly found in nature in its native form, as well as in various minerals and ores. Copper is widely used in electrical wiring, as it is an excellent conductor of electricity and is also resistant to corrosion. It is also used in the production of coins, decorative items, and cookware. Copper alloys such as brass and bronze are used for various applications due to their unique properties, including durability, corrosion resistance, and aesthetic appeal.

India is a significant importer of copper, with the country importing around 4 million metric tons of refined copper in 2020. The demand for copper in India is driven by various industries, including construction, electronics, and transportation. The Indian government has identified copper as a strategic metal and has implemented policies to promote the domestic production of copper.

Zinc

Zinc is one of the most commonly used metals in the world and is widely used in a variety of applications, including galvanizing steel, as a component in batteries, and in the production of alloys.

One of the key properties of zinc is its ability to resist corrosion. This makes it an ideal material for use in outdoor structures and in environments where there is a risk of corrosion, such as marine applications. Zinc is typically extracted from zinc sulfide ores, which are roasted to produce zinc oxide. The zinc oxide is then reduced to metallic zinc using a process called electrolysis.

Zinc has a wide range of uses and is an important element in many industries. Its versatility, durability, and resistance to corrosion make it a valuable material in a wide variety of applications. Zinc metal has significant importance in India as it is used in a wide range of industries, including construction, transportation, and manufacturing. India is the fourth-largest producer of zinc globally, and the metal is primarily mined in the states of Rajasthan, Andhra Pradesh, and Gujarat.

Metal Scrap

Metal scrap refers to any discarded or leftover metal materials that can be recycled and reused. These materials can come from a variety of sources, such as manufacturing, construction, and demolition sites. Common types of metal scrap include steel, aluminum, copper, brass, and iron.

Recycling metal scrap has numerous benefits for the environment and the economy. Recycling metal scrap reduces the amount of waste that ends up in landfills, conserves natural resources, and reduces the energy required to produce new metals from raw materials. Additionally, recycling metal scrap generates jobs and stimulates local economies.

The process of recycling metal scrap involves collecting, sorting, and processing the materials. Scrap metal collectors gather the materials from various sources and transport them to recycling facilities. At the facility, the materials are sorted based on their type and quality. They are then processed and melted down to be formed into new products or materials.